Indoor Construction Layout: From Traditional Methods to Digital Precision

- Tomer Elran

- Jun 6, 2024

- 3 min read

Updated: Feb 16

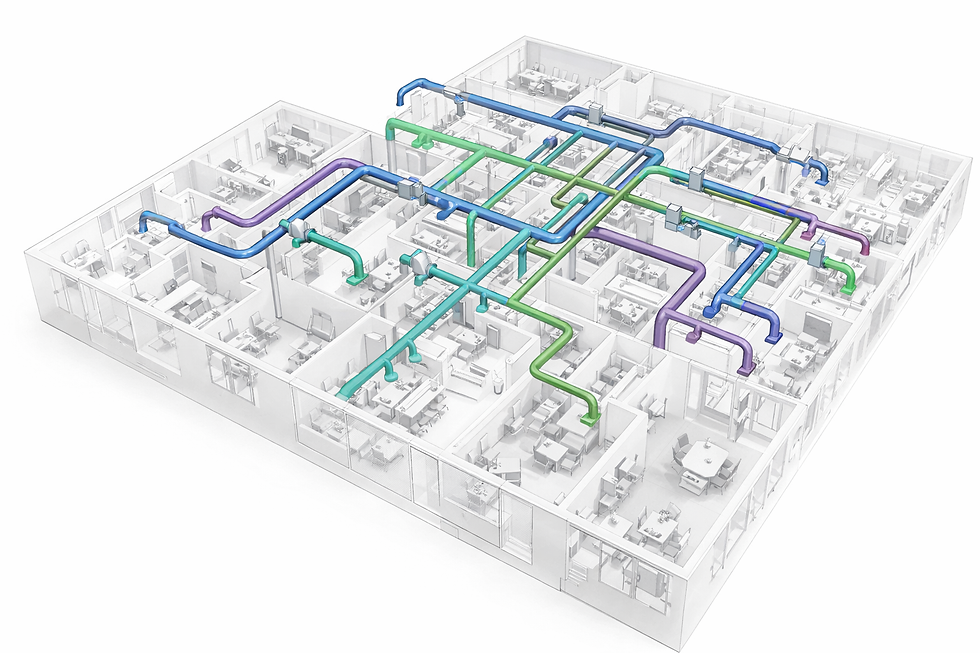

In the world of construction, precise layout is the critical link that connects digital designs and drawings to the tangible structure on-site, and digital construction layout tools have fundamentally changed how that connection is made.. This article delves into the intricate process of indoor construction layout, focusing on both traditional methods and innovative advancements such as robotic total stations and LightYX technology. We will explore how these techniques are revolutionizing the construction industry by improving accuracy, efficiency, and overall project outcomes.

Traditional Construction Layout Methods — and Where They Break Down

Traditionally, the layout process in construction has relied heavily on manual methods. Surveyors and layout professionals would use tools like tape measures, chalk lines, and plumb bobs to transfer designs from blueprints to the construction site. The process, though time-tested, is labor-intensive and prone to human error. Some of the common traditional tools and methods include:

Measuring Tapes and Chalk Lines: Used for marking straight lines and distances, these tools require a significant amount of manual labor and are subject to measurement inaccuracies.

Plumb Bobs and Levels: Essential for ensuring vertical and horizontal accuracy, these tools demand skilled handling to avoid errors.

Theodolites: These precision instruments measure angles in horizontal and vertical planes but require experienced operators and are time-consuming to set up.

While these methods have been the backbone of construction layout for decades, they come with inherent limitations that directly contribute to field rework and project delays.

Modern Digital Construction Layout Tools

The evolution of construction technology has introduced more sophisticated tools that enhance the layout process, reducing errors and increasing efficiency. Two notable advancements are robotic total stations and LightYX systems.

Robotic Total Stations: Accuracy Without the Manual Work

Robotic total stations represent a significant leap forward from traditional theodolites. These advanced instruments automate angle and distance measurements, controlled remotely by a single operator. Key benefits include:

Precision: Robotic total stations provide highly accurate measurements, significantly reducing the margin of error.

Efficiency: The automation of measurements allows for faster data collection and layout marking, expediting the construction process.

Versatility: These stations can integrate with digital design software, ensuring seamless transitions from design to execution.

Laser Layout Projection: Bringing the BIM Model to the Field

LightYX is at the forefront of innovative construction layout technology, using laser projection layout systems to transform digital designs directly onto physical surfaces, LightYX transforms digital designs directly onto physical surfaces, providing a visual guide for construction crews. Key advantages of LightYX include:

Real-Time Projection: Digital drawings are projected onto walls, floors, and ceilings, offering a precise visual representation of the layout.

Increased Accuracy: By minimizing manual measurements, LightYX significantly reduces the risk of errors and rework.

Enhanced Collaboration: The visual clarity provided by LightYX allows all team members to understand the layout instantly, improving coordination and communication on-site.

The Layout: Bridging Digital Design and Real-World Construction

At its core, the layout process is the essential bridge between digital design and real-world construction. It ensures that what is meticulously planned in the design phase is accurately realized on the construction site. The integration of traditional methods with modern technologies like robotic total stations and LightYX exemplifies the industry's shift towards more efficient, precise, and collaborative practices.

By adopting these innovative tools, construction projects can achieve higher quality outcomes, reduce timelines, and minimize costly errors. As technology continues to advance, the future of construction layout promises even greater enhancements, further solidifying the critical role of layout as the bridge between design and reality. For teams ready to move beyond traditional layout, get in touch directly to discuss how LightYX fits your project workflow.