Construction Robotics: A Practical Guide

- Tomer Elran

- Jan 1

- 4 min read

Updated: Jan 12

Robotics in construction has moved from experimental pilots to real jobsite deployment. Today, robots are laying out buildings, drilling overhead anchors, placing bricks, finishing interiors, moving earth, and verifying work against digital models.

This shift is not about replacing skilled labor. It is about addressing real challenges: labor shortages, rework, coordination errors, safety concerns, and increasing reliance on BIM and digital design.

This pillar guide explains what construction robotics is, the main robot categories, how they are used in practice, and how layout robotics — including LightYX — fits into the broader ecosystem.

What Is Construction Robotics?

Construction robotics refers to programmable, automated or semi-automated systems that perform or assist construction tasks using digital input.

Unlike factory robots, construction robots must operate in:

Unstructured, changing environments

Active jobsites with human crews

Dust, vibration, and uneven surfaces

Because of this, construction robotics has evolved as a collection of task-specific systems, each designed to solve a particular high-impact problem.

Why Robotics Matters in Construction

The adoption of robotics is driven by structural industry pressures:

Skilled labor shortages across trades

High rework costs caused by layout and coordination errors

Increasing project complexity

Widespread adoption of BIM and coordinated models

Greater focus on safety and ergonomics

Robotics helps reduce interpretation, increase consistency, and allow skilled workers to focus on higher-value work.

Core Categories of Construction Robotics

Construction robotics can be organized into distinct categories, aligned with different phases of construction.

1. Layout & Positioning Robots

Purpose: Translate digital design data into accurate physical reference on the jobsite.

Layout & positioning robots are often the first robotic systems adopted because layout errors propagate downstream into every trade.

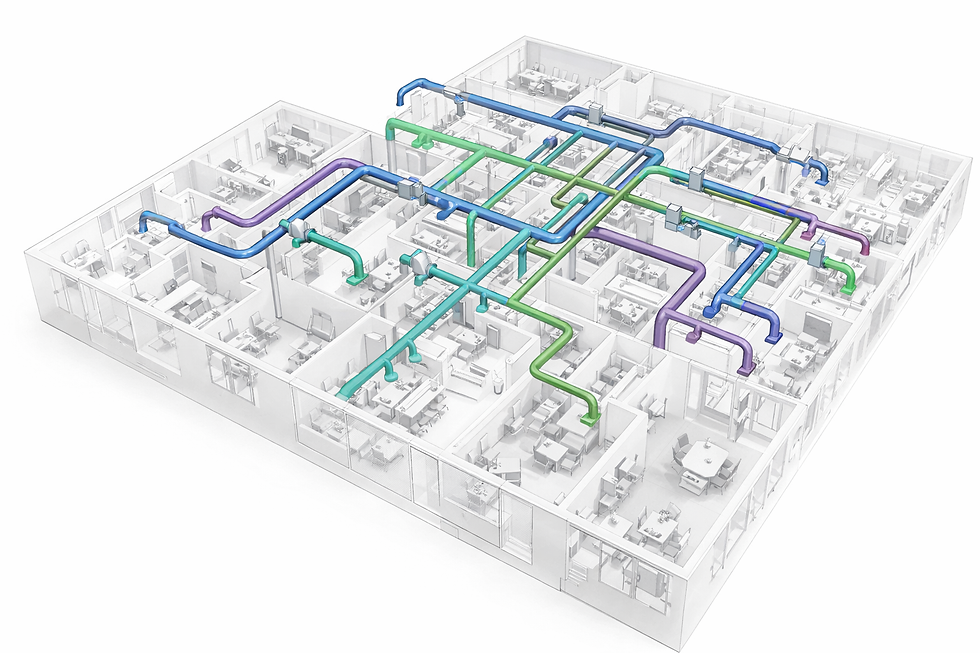

These robots work directly from CAD or BIM data to establish reference geometry on slabs, walls, and ceilings — enabling accurate installation later.

What Layout Robots Do

Establish points, lines, and elevations from digital models

Align physical construction with coordinated design data

Reduce layout time and rework

Improve multi-trade coordination

Two Approaches to Robotic Layout

Robotic Laser Layout

Uses robotic instruments to place or guide individual layout points with high accuracy.

Example

Trimble — Robotic total stations and model-driven layout tools https://construction.trimble.com

Full-Scale Visual Robotic Layout

Projects the entire coordinated layout at full scale directly onto jobsite surfaces.

Instead of marking individual points, crews see walls, penetrations, hangers, openings, and trade elements exactly as designed.

Example

LightYX — Full-scale laser-projected layout and verification

LightYX enables crews to:

Work visually instead of interpreting drawings

Coordinate multiple trades simultaneously

Verify accuracy continuously during installation

LightYX tool projects Layout

Why Robotic Layout Scales

Layout robots:

Improve accuracy without disrupting workflows

Support drywall, MEP, framing, concrete, and prefab

Serve as the foundation layer for other construction robots

2. Drilling, Anchoring Robots

Purpose: Automate repetitive, high-precision drilling and fastening tasks.

These robots are commonly used for overhead drilling for hangers and supports.

What These Robots Do

Drill holes at exact locations and depths

Install anchors, inserts, or supports

Follow predefined digital paths

Operate safely in overhead environments

These robots execute preparation work, not full installations.

Benefits

Consistent placement

Reduced physical strain

Higher productivity

Example

Hilti Jaibot — Robotic overhead drilling and anchor installation

3. Robotic Installation Systems

Bricklaying, Flooring, and Repetitive Assembly

Purpose: Directly place building materials using automated systems.

Unlike layout or drilling robots, these systems execute installation work.

Bricklaying Robots

Automated brick or block placement

Consistent spacing and alignment

High productivity in repetitive wall construction

Examples

Construction Robotics — SAM (Semi-Automated Mason) https://www.constructionrobots.com

FBR — Hadrian X autonomous bricklaying

Robotic Flooring Installation

Flooring robots place tiles or panels in large, standardized spaces. Adoption is growing but remains selective due to material and surface variability.

4. Interior Finishing & Surface Robots

Purpose: Automate physically demanding finishing tasks.

Typical Applications

Drywall finishing

Sanding and plastering

Surface preparation

Examples

Baubothttps://www.baubot.com

5. Earthmoving & Heavy Equipment Automation

Purpose: Automate excavation, grading, and site preparation.

Example

Built Robotics

These systems operate mainly in outdoor, controlled environments.

6. Inspection, Scanning & Verification Robots

Purpose: Capture as-built conditions and verify work against digital design.

Value

Early detection of errors

Faster QA/QC

Better field-office coordination

Many layout systems now combine layout + verification in a single workflow.

Example

Spot by Boston Dynamics

7. Material-Execution Robotics: 3D Construction Printing

3D construction printers are robotic systems, but they belong to a distinct sub-category.

Characteristics

Gantry or robotic-arm based

Automated material extrusion

Operate from digital models

3D printing replaces entire construction steps, requires controlled conditions, and remains niche compared to field-assist robotics.

Example

Spot by Boston Dynamic

Focus: Residential and small commercial concrete construction Technology:

Gantry-based concrete extrusion Use cases:

3D-printed walls and shells

Housing developments

Disaster-relief and rapid housing projects

ICON is one of the most visible companies bringing large-scale 3D concrete printing into real construction programs.

Why BIM Is Central to Construction Robotics

At a fundamental level, construction robotics is an execution layer for digital design.Robots do not interpret drawings the way humans do — they consume structured digital data and execute tasks deterministically.

This makes BIM (Building Information Modeling) and coordinated digital design the single most important prerequisite for successful robotics adoption.

Without accurate, coordinated models:

Robots cannot reliably execute tasks

Errors propagate faster, not slower

Automation amplifies mistakes instead of eliminating them

Robots are only as effective as the digital data they receive.

BIM, coordinated trade models, and accurate shop drawings are the backbone of construction robotics.

How All Categories Work Together

A realistic robotic construction workflow looks like this:

Layout robotics define geometry (Trimble, LightYX)

Drilling robots prepare substrates

Installation robots place materials

Finishing robots refine surfaces

Inspection robots verify execution

Typical Adoption Path in the Field

Most contractors adopt robotics in this order:

Layout & verification robots

Drilling and anchoring robots

Finishing robots

Installation robots (bricklaying, flooring)

3D printing for specific use cases

This reflects ROI clarity, flexibility, and risk tolerance.

Conclusion: Robotics as a Foundation of Modern Construction

Robotics in construction is no longer experimental. It is becoming foundational.

From layout and drilling to installation, finishing, and verification, robots reduce errors, improve safety, and increase productivity. When tied directly to digital design, they enable predictable, model-driven execution.

As construction continues to evolve, robotics will not replace skilled workers — it will amplify their impact and define how modern projects are delivered.